SinoFour help Novartis construction intelligent factory, set up the first set of Milling & Blending production line, is the domestic industry first try, scan widely international also is second to none. Based on the PCS7 system, the process and HMI screen configuration were carried out, and the BATCH management process of the production line was realized, which greatly improved the efficiency and gave full play to the flexibility. Intelligent production is no longer a prediction, but a direct embrace of reality.

NOVARTIS

As one of the three largest pharmaceutical companies in the world, novartis is committed to improving the health and quality of life of the Chinese people through innovative products and services. Novartis is committed to the research, development and production of high-quality innovative drugs to bring patients a longer, healthier and better life.

Milling & Blending

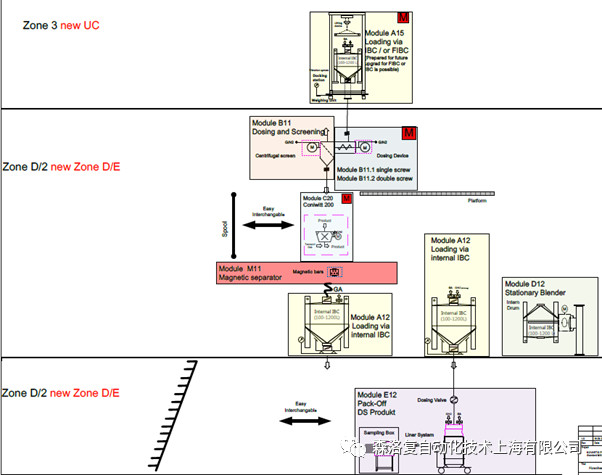

Milling & Blending is the most advanced domestic grinding packaging production line, used for API sieving raw material, milling and packaging, contains the IBC and FIBC two sets of packaging mode. The production line is fully automated from canning, grinding and screening to packaging of finished products. The inefficient production management method is no longer needed and operators are liberated from the heavy and boring production.

Milling & Blending Process Flow Chart

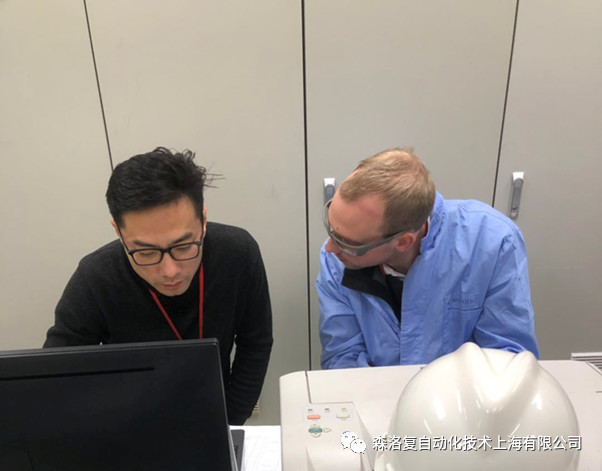

SinoFour engineers have conducted many technical discussions with foreign technical experts to ensure the accuracy of the process

Engineers and foreign technical experts technical exchanges

Engineers and foreign technical experts joint debugging

Technical highlights

SinoFour develops personalized reports that timely and accurately reflect key parameters in the production process for user management and analysis.

BATCH processing technology improves the production efficiency, system reliability and stability, and reduces the labor cost.

Electronic signature and audit tracking function, the key operation needs to enter the specified content of the high-level permission to review, to prevent misoperation, and record historical data, operation records, alarm records and other important parameters, greatly improve the security of the system, in line with the federal regulations 21CFR Part11.

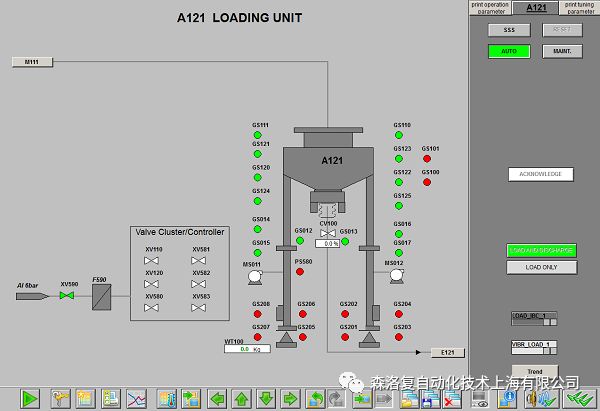

Simple and clear HMI human-computer interaction screen for easy operation.

HMI

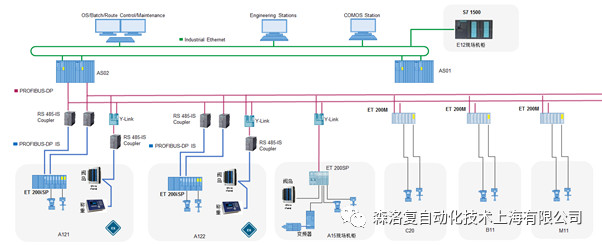

The project integrates a variety of complex third-party communication, including Profibus DP, weighing module, valve island, remote ET200SP and ET200ISP, and Ethernet and botu 1500PLC.

System Network Structure Diagram

The cooperation between SinoFour and Novartis has laid the foundation for the development of domestic automated milling and packaging production line, and is also an important step for SinoFour in the field of automated pharmacy.