Honeywell

Honeywell automation control system group is an international leader in the application of its products, services and technologies in more than 100 million homes and 5 million buildings worldwide.

Walvax Biotechnology Co., Ltd.

Walvax Biotechnology Co.,Ltd. Is a modern biopharmaceutical enterprise engaged in the research and development, production and sales of vaccines and blood products in China, and is a high-tech enterprise recognized by the state and a national enterprise technology center.

13 valent pneumonia vaccine

The 13-valent pneumococcal vaccine is called the "13-valent pneumococcal polysaccharide conjugate vaccine". It is a conjugate vaccine which contains 13 kinds of pathogen antigens that can cause disease and disability. Pneumococcal infection kills a million people a year, and the 13-valent pneumococcal vaccine provides effective protection for infants and young children. At present, Walvax is the second enterprise in the world and the first enterprise in China to successfully develop the 13-price pneumococcal vaccine after the production workshop of pneumococcal vaccine is put into production, which will alleviate the current situation of insufficient supply of 13-price pneumococcal vaccine in China and ensure the safety of the supply of pneumococcal disease prevention vaccine in China.

Project details

Yunnan Walvax BMS&EMS system SinoFour developed BMS&EMS program based on Honeywell PKS system, drew HMI(human-computer interaction) interface and wrote verification documents to help Watson pass the review of eu-gmp and US FDA. The FAT(factory acceptance test) of this project has been successfully completed and will be moved to the next stage. Walvax highly recognized the professionalism of SinoFour and Honeywell, as well as their responsible and serious attitude towards work.

Project window

1、The system platform is fully virtualized. It not only saves the hardware cost for users, but also extends the upgrade cycle of the system, reduces the life cycle cost of the system, simplifies the system management, improves the availability and reliability, and realizes rapid disaster recovery.

2、The system adopts FTE(fault - tolerant Ethernet) technology. FTE technology greatly reduces the user's operation and maintenance costs, and FTE does not have the blind spot time of network switching, and can withstand more failures, providing an ideal effect for enhancing the usability and reliability of the system.

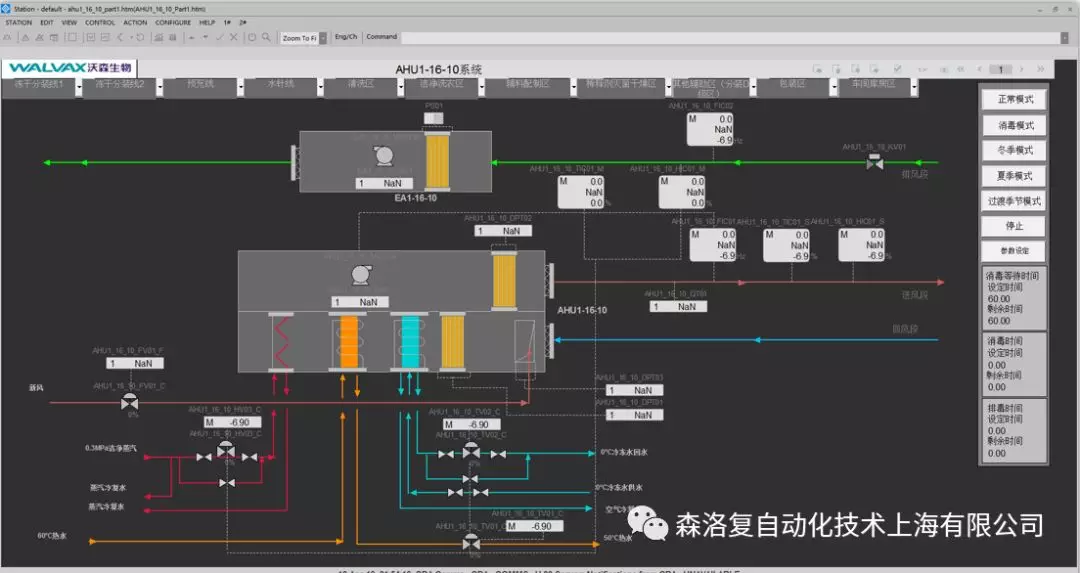

HMI screen configuration

The HMI screen of the BMS&EMS system is concise and easy for operators to operate.

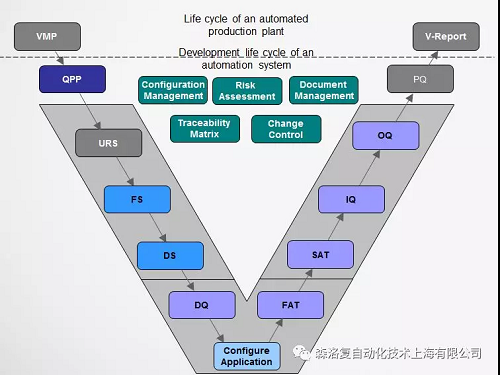

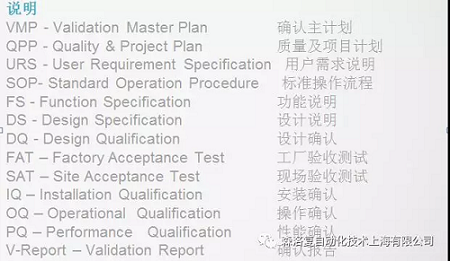

CSV computerized system verification process

The system platform is fully virtualized. It not only saves the hardware cost for users, but also extends the upgrade cycle of the system, reduces the life cycle cost of the system, simplifies the system management, improves the availability and reliability, and realizes rapid disaster recovery.

FAT hardware testing

The engineer shall test the clamp channel of the cabinet to ensure the correct wiring of each clamp and the normal channel.

FAT software testing

Engineers perform software functional tests to ensure that the system functions as designed.